In Stock

Engineering LCD Series Flex 82A Resin (Copy)

Features & Advantages

- Combines semi-flexibility with strength

- Shore hardness 82A

- High printer compatibility

- Perfect for seals & soft-touch applications

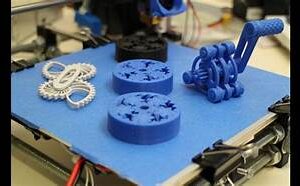

r Flexible 3D Printer Resins category offers a large selection of high-quality and flexible resins for 3D printing. These resins are perfect for printing flexible and durable parts like rubber or TPE.

Our Flexible 3D Printer Resins are from reputable manufacturers and have been carefully selected to ensure the best quality and performance. They are also available in a variety of colours so you can fully express your creative ideas.

Filter & sort

-

The Engineering LCD Resin – Flex 82A is a rubber-like resin that combines semi-flexibility with strength and whose material properties are similar to those of TPU. With a Shore hardness of 82A, the resin withstands frequent loads from bending and pressure.

Main Features of Engineering LCD Series Flex 82A – Resin

- Material properties similar to rubber

- Good elasticity against bending and compression

- Excellent material properties in terms of cushioning and shock absorption

- Good compatibility with all SLA, DLP and LCD / MSLA 3D printers in the range of 385 – 420nm

Applications of Engineering LCD Series Flex 82A – Resin

- Custom-fit seals

- Wearables and soft-touch applications

- Mechanical and operational spare parts

- Handles

- Small batch production

Before you start printing

- Shake the bottle for at least 2 minutes before each use

- After shaking the bottle, let the resin sit for 10 minutes to allow air bubbles to escape from the resin.

- Always wear safety glasses and nitrile gloves when handling resin.

Note: The unused resin can be poured back into the bottle after the print is finished.

Post-processing

- The manufacturer recommends post-processing the print in order to achieve the best material properties.

- Rinse your model in IPA or ethanol for about 5 minutes.

- An ultrasonic cleaner is recommended.

- Make sure objects rinsed with IPA and/or ethanol are perfectly dry before further post-curing.

- Place the rinsed parts in a well-ventilated area for at least 30 minutes or use compressed air for at least 2 minutes.

- Cure your object in a high-performance curing chamber for approx. 20-30 minutes at 65 ° C. The preferred curing wavelength is between 300-410 nm.

Bestsellers

x3d model extra hard

£28.00 – £50.00x3d model shellac

£28.00 – £50.00x3d flex cast

£28.00 – £50.00eResin-PLA Pro White, 1.000 g

-

Features & Advantages

- Special dental resin

- High surface hardness & dimensional stability

- Good strength & toughness

- Low shrinkage

Engineering SLA Series Tough Clear, 500 g

- Key Features

- High impact resistance

- Good UV and weather resistance

- Good fatigue resistance

- Extremely transparent, virtually no discolouration and/or yellowing

- High dimensional accuracy and low shrinkage

- Almost odourless processing

- Compatible with all open-source SLA, DLP and LCD 3D printers in the range of 385 to 405 nm

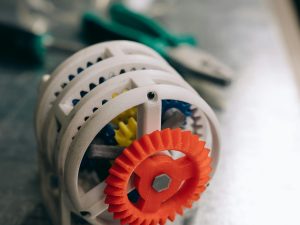

- Snap connections

- Tools

- Functional prototyping

- Covers

- Exterior parts

- Production in small quantities

- Flawlessly smooth surfaces

- High precision

Water-washable Resin

-

-

Features & Advantages

- Outstanding precision

- Excellent flowability

- Brilliant colours

- Versatile in use

-

Features & Advantages

Engineering LCD Series Flex 82A Resin

- Combines semi-flexibility with strength

- Shore hardness 82A

- High printer compatibility

- Perfect for seals & soft-touch applications

Reviews

There are no reviews yet.